Rust and corrosion are two of the most common and damaging issues faced by air conditioning (AC) systems, particularly in environments with high humidity or exposure to saltwater. While these problems may seem insignificant at first, they can have a major impact on the efficiency, performance, and longevity of your AC system. Understanding how rust and corrosion affect air conditioning systems can help homeowners and businesses take preventative measures to avoid costly repairs or system replacements.

What is Rust and Corrosion?

- Rust is the result of the oxidation of metals, typically iron or steel, when exposed to oxygen and moisture. This process forms a reddish-brown layer of iron oxide on the surface of the metal.

- Corrosion refers to the gradual destruction or degradation of materials, often metals, caused by chemical reactions with their environment. In the context of air conditioning systems, corrosion usually affects parts like coils, fins, and metal housing components. It can occur from exposure to air, moisture, chemicals, or environmental factors such as salty air.

Both rust and corrosion compromise the structural integrity and functionality of air conditioning systems, leading to reduced efficiency, increased repair costs, and even system failure if left untreated.

How Rust and Corrosion Impact Air Conditioning Components

1. Coils (Evaporator and Condenser)

Coils are crucial for the heat exchange process in air conditioning systems. The evaporator coil absorbs heat from the air, and the condenser coil releases the heat outside. These coils are typically made of copper, aluminum, or steel, materials that are vulnerable to rust and corrosion under the right conditions.

- Corrosion of Coils: When the coils corrode, their efficiency in heat transfer is diminished. This leads to an increase in energy consumption as the AC system works harder to maintain the desired temperature.

- Rust and Leaks: Rust on the metal surfaces of the coils can cause holes or cracks. This not only reduces the system’s ability to cool effectively but can also lead to refrigerant leaks, which are harmful to both the environment and the system’s performance.

2. Copper Tubing and Piping

Copper is a commonly used material for refrigerant lines and tubing in air conditioners. It is durable but still susceptible to corrosion and rust over time, particularly when exposed to moisture or air pollutants.

- Corrosion of Copper Pipes: Corrosion of copper pipes leads to leaks in the refrigerant system, reducing the cooling efficiency and causing the compressor to work harder. This can lead to overheating and, ultimately, system failure.

- Pitting Corrosion: In humid environments, especially near the coast, copper pipes can develop pitting corrosion, which causes tiny holes that may be difficult to detect at first. These leaks can reduce refrigerant levels, causing the system to underperform and leading to costly repairs.

3. Air Conditioner Fins (Evaporator and Condenser Fins)

The fins on the evaporator and condenser coils help with airflow and heat dissipation. These fins are typically made of aluminum, which is prone to corrosion, especially in salty or acidic environments.

- Damage to Fins: When aluminum fins corrode or rust, they can become brittle and break off. This compromises the airflow, making the AC system less efficient and causing the unit to overheat.

- Reduced Heat Transfer: Corrosion reduces the surface area of the fins, which in turn reduces the system’s ability to exchange heat efficiently. This results in reduced cooling power and increased energy usage.

4. Compressor and Motor Components

The compressor, which is the heart of an air conditioning system, is responsible for circulating refrigerant throughout the system. It is usually housed in a metal casing, which can rust over time, particularly if the AC unit is exposed to moisture or humidity.

- Corrosion of Compressor Housing: Rust or corrosion on the compressor housing can lead to the motor overheating or seizing up. This damages the system’s ability to circulate refrigerant and causes the entire unit to fail.

- Internal Damage: Rust can spread from the external components of the system to the internal working parts. For example, rust particles from corroded metal can clog and damage the compressor’s internal mechanisms, leading to costly repairs or replacement.

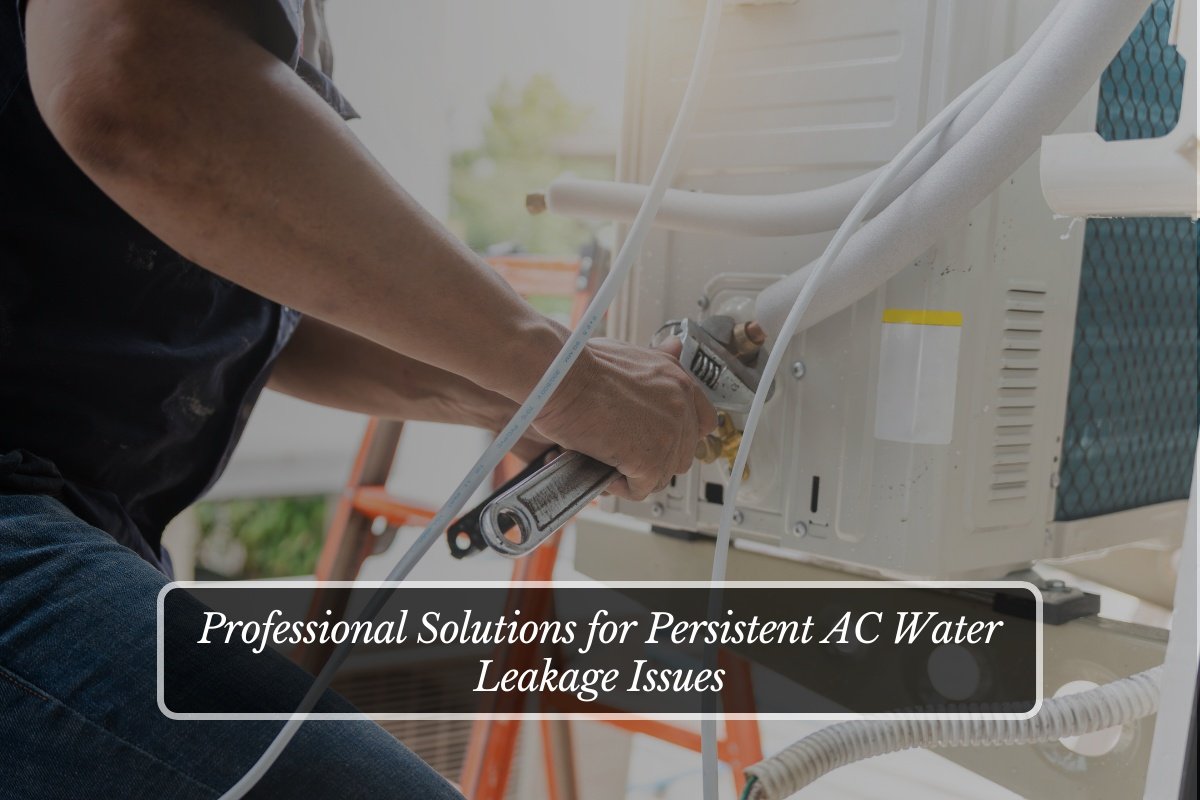

5. Drain Lines and Pans

AC systems produce condensation as they cool air, and this moisture is collected in the drain pan and channeled out through drain lines. These parts are often made of plastic or metal, but over time, metal drain pans can develop rust.

- Corrosion in Drain Lines: If rust or corrosion occurs in the drain pan or lines, it can lead to blockages or leaks. These issues can cause water damage around the AC unit and lead to mold growth, which can be hazardous to health and costly to remove.

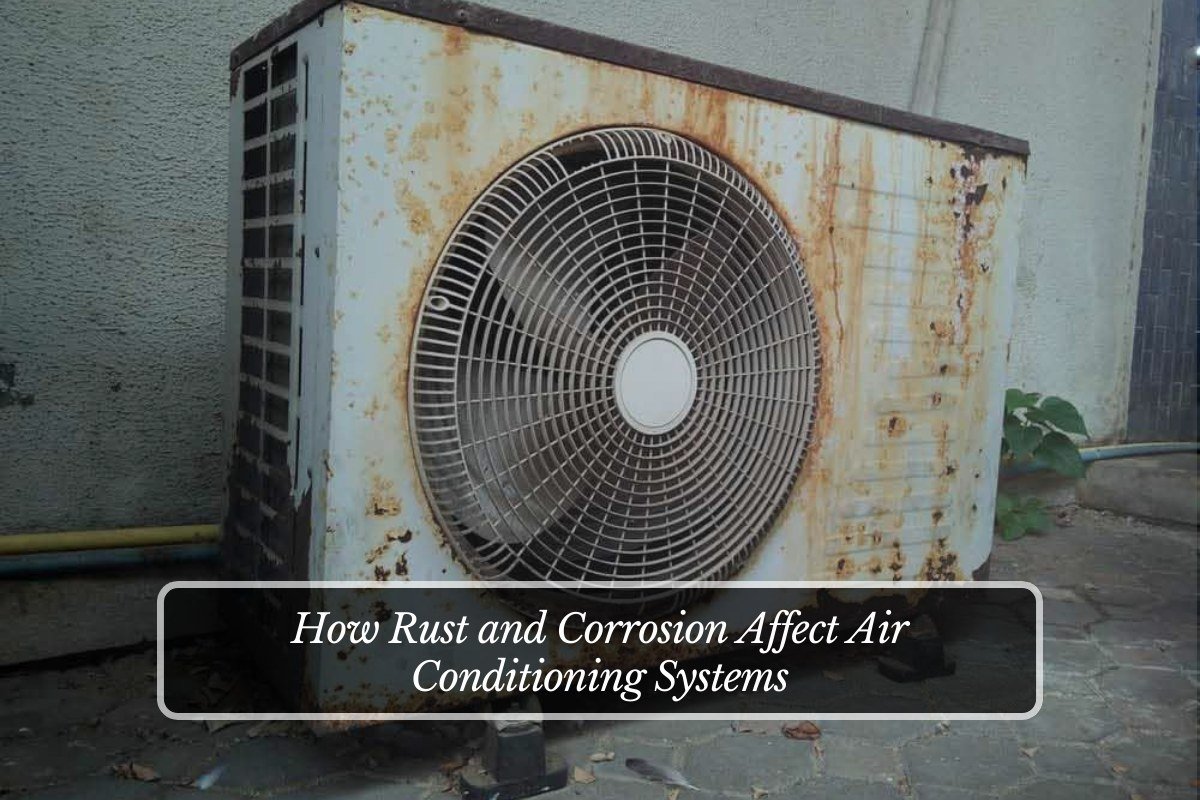

6. Outdoor Unit and Housing

The outdoor unit of an air conditioner is especially vulnerable to rust and corrosion because it is exposed to the elements. Rain, humidity, and pollutants can cause rust to form on the housing and metal components of the outdoor unit.

- Rust on Housing: The outdoor unit’s housing can rust over time, especially if it’s located in a coastal area where saltwater is present. Rust can weaken the structure of the unit, causing it to degrade prematurely and reducing its lifespan.

- Corrosion of Grills and Protective Panels: The protective panels and grills on the outdoor unit can corrode, leading to reduced protection for the internal components. This can increase the risk of dirt, debris, and pests damaging the internal components.

The Impact on Energy Efficiency

Rust and corrosion directly affect the energy efficiency of an air conditioning system. When key components like coils, fins, and pipes are compromised, the system has to work harder to achieve the desired cooling levels. This leads to:

- Increased Energy Consumption: Corroded or rusted components, such as damaged coils and clogged drain lines, force the AC system to use more energy to cool the space, increasing electricity bills.

- Longer Running Time: A system with reduced efficiency will need to run longer cycles to maintain the desired temperature, leading to more wear and tear and a higher energy bill.

Preventing Rust and Corrosion

Preventing rust and corrosion is essential for maintaining the longevity and efficiency of your air conditioning system. Here are some proactive measures:

- Regular Cleaning and Maintenance: Periodically cleaning the coils, fins, and filters will help prevent rust and corrosion buildup. Proper maintenance, including checking for leaks and cleaning drain lines, ensures optimal performance.

- Protective Coatings: Applying protective coatings to vulnerable components, especially in areas with high humidity or coastal exposure, can prevent rust from forming. These coatings can help protect coils, pipes, and other metal parts.

- Proper Drainage: Ensure the drain lines and pans are free from debris and that the system is properly draining to avoid moisture buildup, which accelerates corrosion.

- Environmental Control: If you live in a coastal area with high humidity or salty air, consider using a corrosion-resistant air conditioning system or installing a dehumidifier to reduce moisture levels around the unit.

FAQs

How does rust affect the performance of air conditioners?

Rust compromises the structural integrity of air conditioning components like coils, pipes, and compressors, reducing efficiency and causing energy wastage. It can also lead to refrigerant leaks and system breakdowns.

Can corrosion be prevented in air conditioning systems?

Yes, regular cleaning, the use of protective coatings, and ensuring proper drainage can help prevent corrosion. In areas with high humidity or salt exposure, corrosion-resistant systems are also recommended.

What happens if the coils become corroded?

Corroded coils lead to reduced heat exchange, making the air conditioner less efficient. This can cause the system to consume more energy and eventually lead to costly repairs or system failure.

How can I prevent rust in my outdoor unit?

Regularly cleaning the outdoor unit, applying protective coatings, and ensuring it is placed in a dry area away from saltwater exposure can help prevent rust on the housing and components.